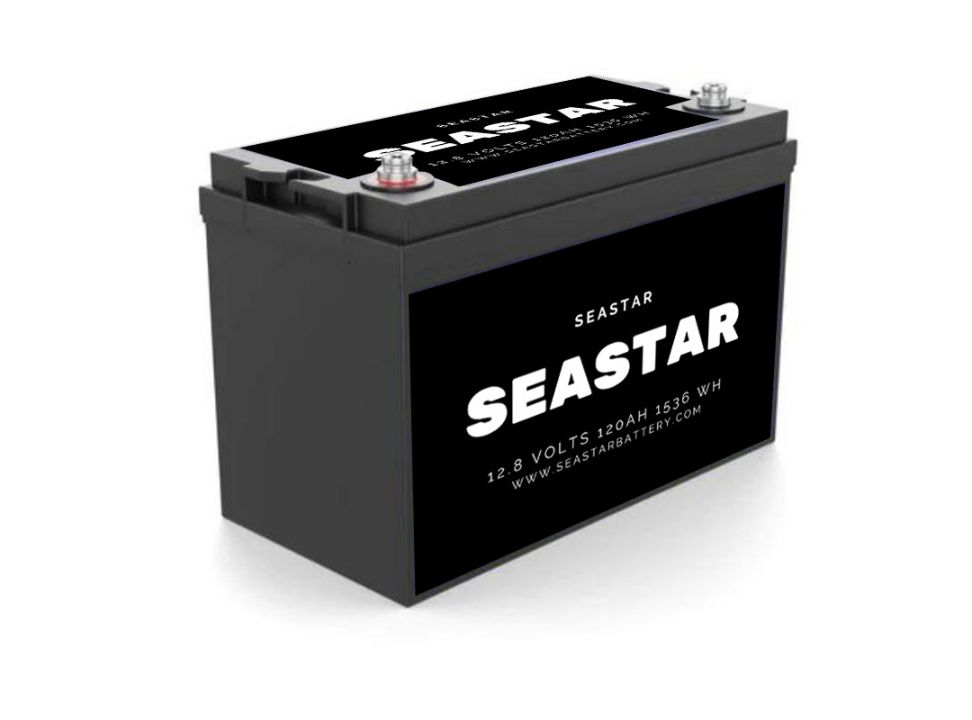

Най-добрите решения за 100Ah литиево-йонни батерии: Seastar Battery отговаря на вашите нужди

Като утвърден производител на литиево-йонни батерии в Китай, Seastar Battery предоставя висококачествени решения за международни клиенти.

Ако търсите “Акумулатор 100ah в София” или “100ah акумулатор доставка в България”, нашите продукти са специално създадени да отговорят на изискванията на пазара.

Тази статия ще разгледа ключовите аспекти, които бизнес клиентите търсят при закупуване на 100Ah литиево-йонни батерии, включително цена, производителност, технически характеристики, и дългосрочна надеждност.

Table of Contents

Основни предимства на 100Ah литиево-йонни батерии от Seastar Battery

Конкурентна цена и висока стойност

- Най-добра цена за качеството: Ние разбираме значението на добра стойност и предлагаме батерии, които съчетават качество и достъпност.

- Ценова прозрачност: Ясна информация за цените, която помага за вземане на информирано решение, идеално за клиенти, които търсят “Акумулатор 100ah с най-добра цена”.

- Опции за закупуване на едро: Отстъпки за големи поръчки, които намаляват разходите за вашия бизнес.

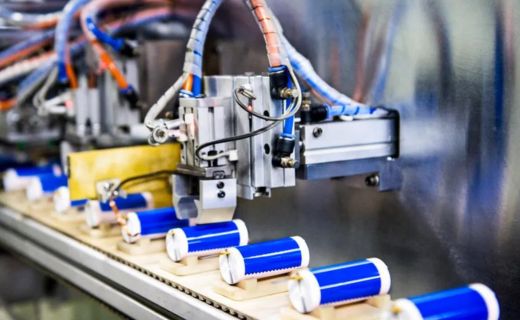

Технологични иновации и производителност

- Дълбок цикъл и дълъг живот: С над 4000 цикъла на заряд/разряд, нашите литиево-йонни батерии надминават стандартните AGM и Gel батерии.

- Поддръжка на висока мощност: Идеални за различни приложения, нашите батерии могат да захранват устройства с голяма мощност, отговаряйки на въпроси като “Колко вата издържа акумулатор 100ah”.

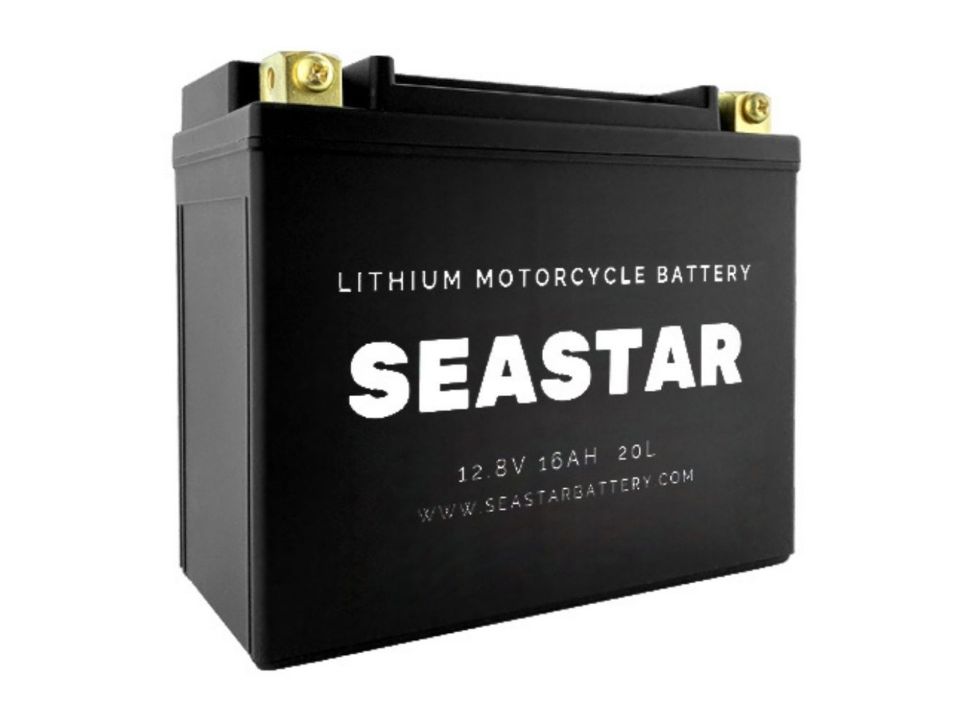

- Съвместимост с водещи технологии: Перфектна алтернатива на Varta, Bosch и други популярни марки, с по-добра енергийна ефективност.

Лесна доставка и персонализирани решения

- Глобална логистика: Предоставяме бърза доставка в България и други източноевропейски страни, което улеснява бизнеса ви.

- OEM и ODM услуги: Ако търсите уникални модели или брандиране за вашия бизнес, ние сме готови да създадем персонализирани решения.

Seastar Battery срещу други марки: Сравнение

| Характеристика | Seastar Battery | Varta | Bosch | AGM Batteries |

|---|---|---|---|---|

| Живот на батерията (цикли) | Над 4000 цикъла | ~600 цикъла | ~700 цикъла | ~800 цикъла |

| Енергийна ефективност | Висока | Средна | Средна | Ниска |

| Цена/Качество | Отлично | Добро | Добро | Средно |

| Опции за персонализиране | Да (OEM/ODM) | Ограничени | Ограничени | Почти липсващи |

Често задавани въпроси (FAQ)

Цените варират според обема на поръчката и изискванията за персонализация. Свържете се с нашия екип за индивидуална оферта.

Нашите литиево-йонни батерии са с по-дълъг живот, по-висока ефективност и са по-леки от стандартните AGM батерии.

Да, предлагаме OEM и ODM услуги, включително брандиране и специфични технически характеристики.

Доверете се на Seastar Battery за вашите 100Ah литиево-йонни батерии

Ако планирате да закупите висококачествени 100Ah литиево-йонни батерии за вашия бизнес, Seastar Battery е вашият надежден партньор.

С доказано качество, конкурентни цени и възможност за глобална доставка, ние сме готови да отговорим на всичките ви изисквания.

Посетете нашия уебсайт seastarbattery.com, за да получите оферта или да научите повече за нашите продукти. Вашето решение за високоефективни батерии започва тук!