Important considerations for assembling lithium battery packs in a factory

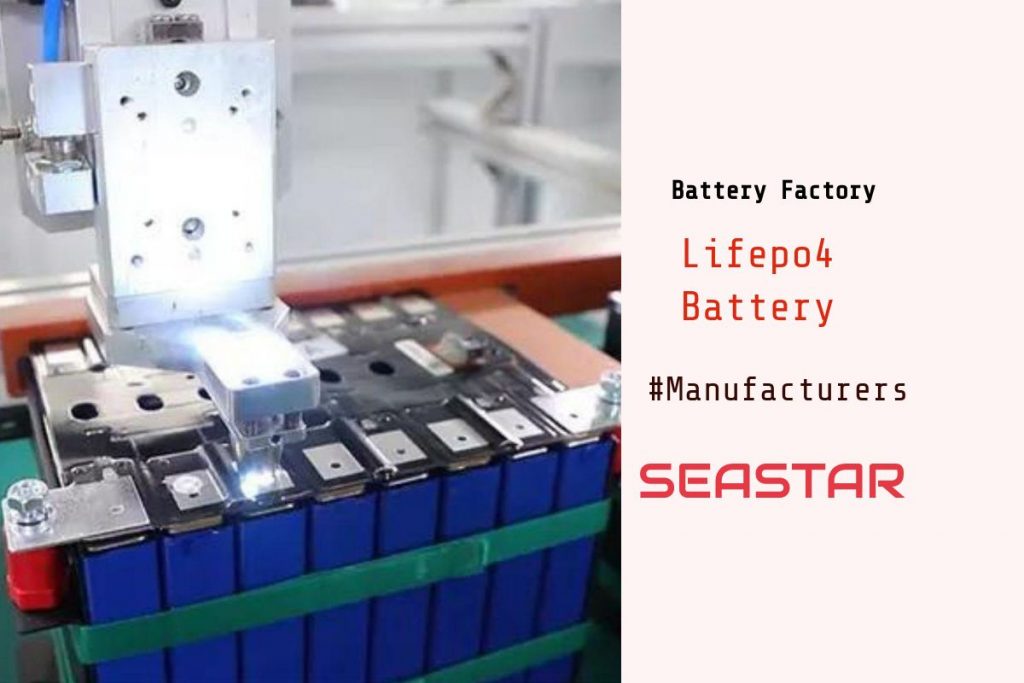

In the heart of the lithium battery revolution, where energy meets ingenuity, Seastar Battery stands as a beacon of excellence. Assembling lithium battery packs in a factory is no ordinary task—it’s a thrilling dance of precision and power. Imagine a symphony of skilled technicians and cutting-edge machinery, harmonizing to create the beating heart of modern energy solutions.

Welcome to the world of Seastar Battery, where we unravel the secrets behind successful lithium battery pack assembly. Today, we invite you to dive into the realm of innovation as we explore the vital considerations that drive our factory’s success. From meticulous design and quality control to efficient manufacturing processes, each step plays a vital role in crafting batteries that redefine performance.

So, fasten your seatbelts and prepare for a thrilling journey into the fascinating world of assembling lithium battery packs. Let’s embark together on this electrifying adventure and discover the power that lies within these remarkable energy storage solutions. Are you ready to witness the future unfolding before your eyes? Let’s explore the artistry of lithium battery pack assembly and unlock the limitless possibilities that lie ahead.

Lithium-ion battery packs are highly versatile and widely used in various industries. By connecting 3.7V lithium-ion single cells in series and parallel configurations, it is possible to achieve high voltage and high capacity battery packs, customized to meet specific customer needs. Discover how this cutting-edge technology is powering the future.

Lithium-ion battery packs are lithium-ion batteries connected in series or parallel to meet a certain want. Many people choose to make their own lithium-ion battery packs in order to save money and, of course, for their own hobby.

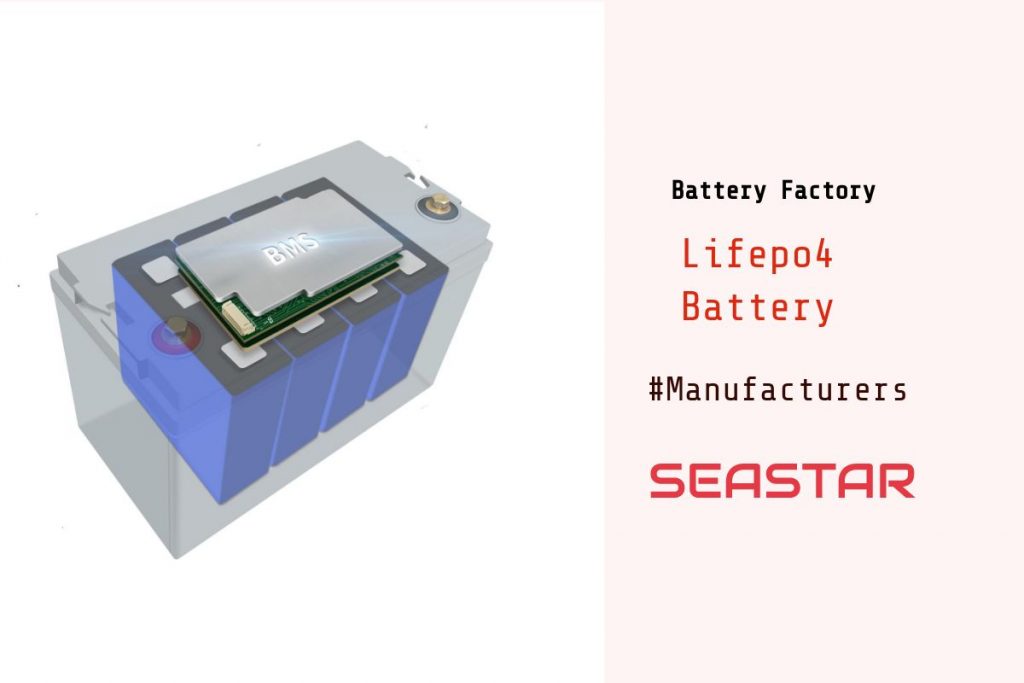

Protecting lithium-ion battery packs from overcharging, over-discharging, and uneven cell capacity is crucial for ensuring their longevity and safety. That’s where a high-quality protection board comes in.

With a good protection board, every string of cells within the battery pack can be effectively safeguarded from these potential issues, while also ensuring that all cells are charged to full capacity. No more worrying about some cells being full while others are still far from it.

Investing in a top-notch protection board is an essential step for anyone looking to get the most out of their lithium-ion batteries. Don’t take any chances with your devices–make sure they’re protected with the best.

The lithium-ion battery pack in the assembly process is important to note the following points:

- each single lithium-ion battery should be matched with capacity, internal resistance, voltage, and other parameters. At the same time pick out the self-discharge inconsistent cells.

- Reasonable design of the protection plate shape and charge/discharge protection voltage values, as well as overcurrent protection values.

- Consider the direction of the nickel strip and wires of the battery pack to prevent short circuits and the existence of short circuit hazards.

- After assembling the lithium-ion battery pack, simulate and test the performance according to the actual demand, and test the basic performance of the battery at the same time

What to Consider in the Production of Lithium-Ion Batteries

To successfully produce lithium-ion batteries, it’s vital to pay attention to these 5 crucial steps, from selecting the right materials to testing the final product:

First, improve the physical and chemical structure of the positive and negative active materials, which is the basic link of the lithium-ion battery production process:

- Appropriate ion doping of the material.

- improve the particle size dispersion of the active material, to prevent the particle size dispersion of the active material is too wide.

- Use materials with disordered layer structure or thin layer structure as far as possible.

- Improve the appearance structure of the electrode material.

Second, the high bonding strength of the electrode coating is conducive to reducing the cycle capacity decline rate, which is the most technical process in the production process of lithium-ion batteries, to which attention should be paid to:

- the binder and solvent that constitute the adhesive material should be pure, and the coated electrode sheet should not be stored for too long.

- positive and negative electrode coating in the mix of adhesive and the active material is used in the appropriate ratio to ensure that the coating does not fall off the powder, no powder.

Third, the optimization of electrolyte composition, lithium-ion battery production process requirements related to the electrolyte is to adhere to the capacity, and extend the life of the battery: 1, after the lithium salt, solvent, and solvent and the battery life:

- through the optimization of lithium salts, solvents, and additives, to improve electrolyte conductivity, reduce polarization

- Inhibit the reaction between cathode material and electrolyte

- through the control of the appropriate specific surface area and carbon anode material for coating, film formation, and appearance of chemical reactions and other exterior treatments, to improve the appearance of the negative electrode material structure.

Fourth, after the battery material preparation is completed, the lithium-ion battery production process will enter the assembly process, at which time attention should be paid to:

- the capacity of the negative electrode is slightly larger than the capacity of the positive electrode.

- after winding the positive and negative electrode and the divider, the gap between the positive and negative electrode sheets and the divider is not larger than 0.5mm, and the deviation between the top and bottom is not more than 0.5mm.

Fifth, the sub-capacity test, in accordance with national standards, with low rate charging is appropriate, generally 0.2C.

In general, the following proportional relationships should be emphasized in the process production stage: pole surface and pole compaction density, negative excess rate, formulation process, electrolyte, and positive and negative electrode blending applicable amount.

Each step in the production process of lithium-ion batteries has a different moment, in general, the ingredients, baking, into a long moment, less than 10 hours or so, more than two days and two nights; other processes are faster, even 5, 6 hours. The entire lithium-ion battery production process takes about 15 days.

Important considerations for assembling lithium battery packs in a factory Read More »