Best Lithium Battery for Car Audio: The Ultimate Guide for Optimal Performance

Selecting the right lithium battery is critical for optimal performance in high-demand car audio systems.

Whether you’re a car audio enthusiast, a competition participant, or managing commercial vehicles, having a reliable battery ensures stable power delivery without interruptions.

Below is a detailed look at some of the best-selling lithium batteries on the market, including SeastarBattery and other industry-leading brands.

Table of Contents

Top-Selling Lithium Batteries for Car Audio

Limitless Lithium Cyber 12K V2

Capacity: 45Ah

Power Output: 10,000-14,000 watts, based on alternator performance.

Special Feature: Integrates seamlessly with older Limitless Blue batteries for flexible setups.

Best For: High-powered audio systems used in competitions or modified cars demanding peak performance.

Dakota Lithium 12V 100Ah LiFePO4 Battery

Capacity: 100Ah

Cycle Life: Over 2500 cycles, with an expected lifespan of 11 years.

Applications: Ideal for RVs, marine setups, and professional audio installations.

Advantages: Lightweight, fast-charging, and highly durable, perfect for intensive usage.

Feature: Built-in Battery Management System (BMS) ensures overcharge and short-circuit protection.

ExpertPower 12V 100Ah LiFePO4 Battery

Capacity: 100Ah

Weight: One-third of a lead-acid battery’s weight.

Cycle Life: 2500-7000 cycles, with a 10-year lifespan.

Use Case: Excellent for both casual and professional audio setups requiring lightweight solutions.

Feature: Includes an integrated BMS for enhanced safety.

XS Power D3400 AGM Battery

Output: 3300 watts

Description: Though not a lithium battery, the XS Power D3400 is a top performer known for its high instantaneous output, making it popular for car audio systems.

Application: Best for users needing high burst power for subwoofers and amplifiers.

Pros: Quick charging, stable performance under heavy loads.

Droppin HZ Car Audio Lithium Battery

Description: Designed specifically for car audio enthusiasts, offering high-current output to support powerful bass.

Application: Perfect for competitions and mobile audio setups requiring extreme performance.

Advantages: High reserve capacity and deep-cycle capability, ensuring smooth operation even during extended use.

Why Lithium Batteries Are Perfect for Car Audio Systems

High CCA (Cold Cranking Amps)

Batteries like the TYKOOL 12V 60Ah provide 1500 CCA, ensuring consistent power during intense bass drops

Deep Cycle Performance

Deep-cycle lithium batteries allow frequent charging and discharging, making them ideal for competitions or events

Reserve Capacity

Batteries with high reserve capacity, such as Droppin HZ models, provide uninterrupted operation during long sessions

Lightweight Design

Lithium batteries are much lighter than traditional lead-acid models, improving fuel efficiency and ease of installation

SeastarBattery: A Competitive New Player in the Market

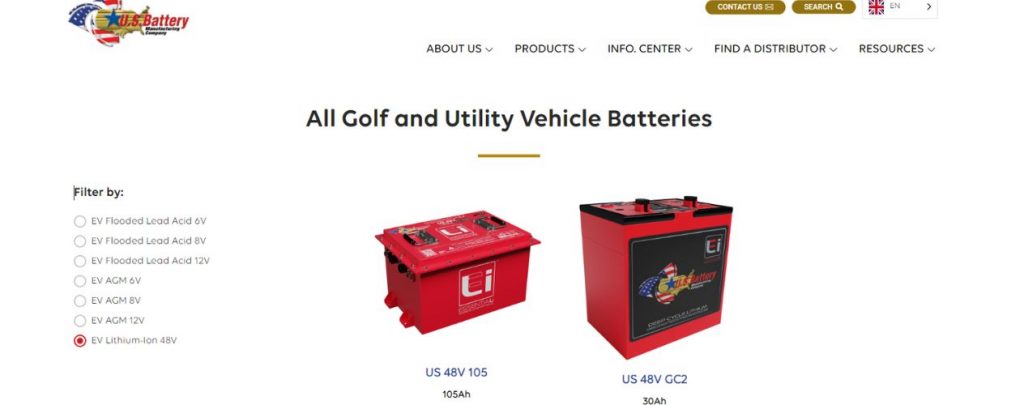

1. Seastar 12V 100Ah LiFePO4 Battery

Capacity: 100Ah

CCA: 1000

Weight: 22 lbs (10 kg)

Use Case: Provides stable power for audio setups, reducing strain on the primary battery.

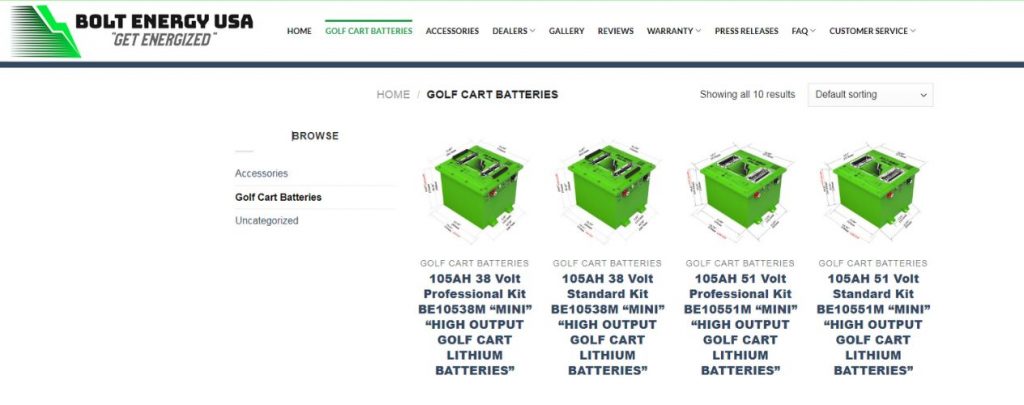

2. Seastar 48V 105Ah LiFePO4 Battery

Capacity: 105Ah

Best For: Suitable for commercial vehicles with complex audio requirements.

Feature: Quick recharge capability and deep-cycle design for continuous operation under heavy loads.

Tips for Installation and Maintenance

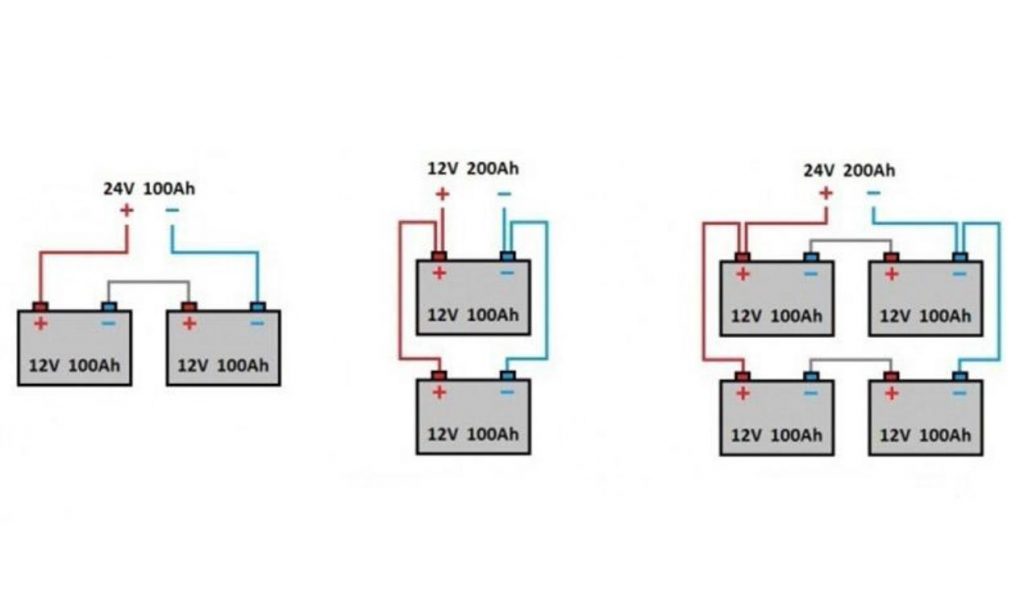

- Parallel Connections for Capacity Expansion: Connect multiple batteries in parallel to increase amp-hour capacity while maintaining the same voltage.

- Battery Isolators for System Protection: Use a battery isolator to ensure the secondary battery powers the audio system independently, protecting the primary battery.

- Ensure Proper Ventilation: Maintain airflow around the batteries to prevent overheating during operation.

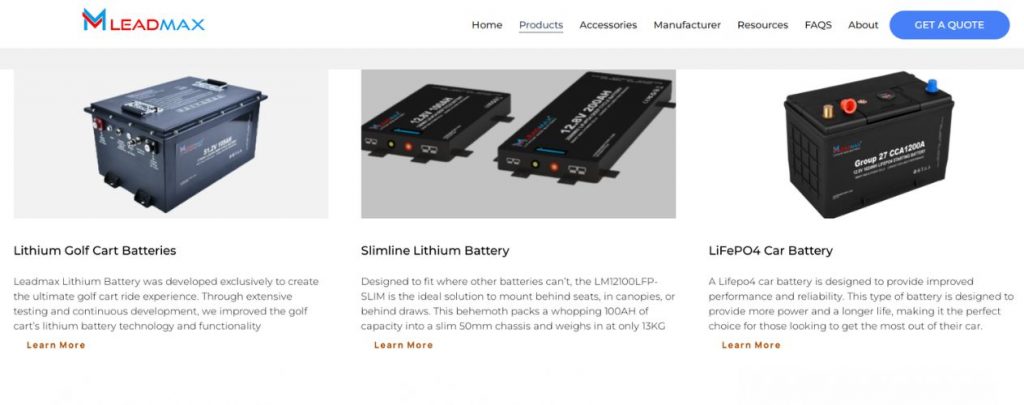

Conclusion: Find the Right Battery for Your Car Audio Setup

Choosing the right lithium battery ensures reliable performance and seamless operation for any audio system.

Whether you need a lightweight, fast-charging option for daily use or a high-capacity model for competition-level setups, the right battery will enhance your audio experience.

SeastarBattery offers competitive products like the 12V 100Ah and 48V 105Ah, standing out as excellent alternatives to brands like Limitless Lithium and Dakota Lithium.

With features such as deep-cycle capability, high CCA ratings, and reserve capacity, these batteries are designed to meet the needs of enthusiasts, professionals, and commercial operators alike.

Equip your system with the right battery and enjoy uninterrupted, high-quality audio in every scenario.

Best Lithium Battery for Car Audio: The Ultimate Guide for Optimal Performance Read More »